PRODUCTION PROCESS

Designing sound that fills space.

Creating a realistic soundstage is what drives Alessandro Schiavi during the design process. The aim is a speaker system that reproduces a natural-sounding environment, replicating the same sensations experienced at live music events.

To achieve this, each speaker cabinet is studied in detail and designed to create a musical point source - an instrument with optimal sound that propagates from the speakers and progresses through an almost spherical shape, leaving the music free to expand thanks to the absence of angles, as if the cabinet receded with the spread of the melody.

The design phase is followed by intensive prototyping and testing, and culminates in the lengthy and characteristic tuning process carried out by Alessandro Schiavi personally.

Thanks to musical experience and an expert ear developed over the years, the tuning process enables lines, form and proportion inside and outside the cabinet to be adjusted for optimal sound propagation and stereophonic harmony.

As a result the ear receives a complete sound sensation, well beyond the parameters verified by software and calculations.

Emotion takes shape in the wood.

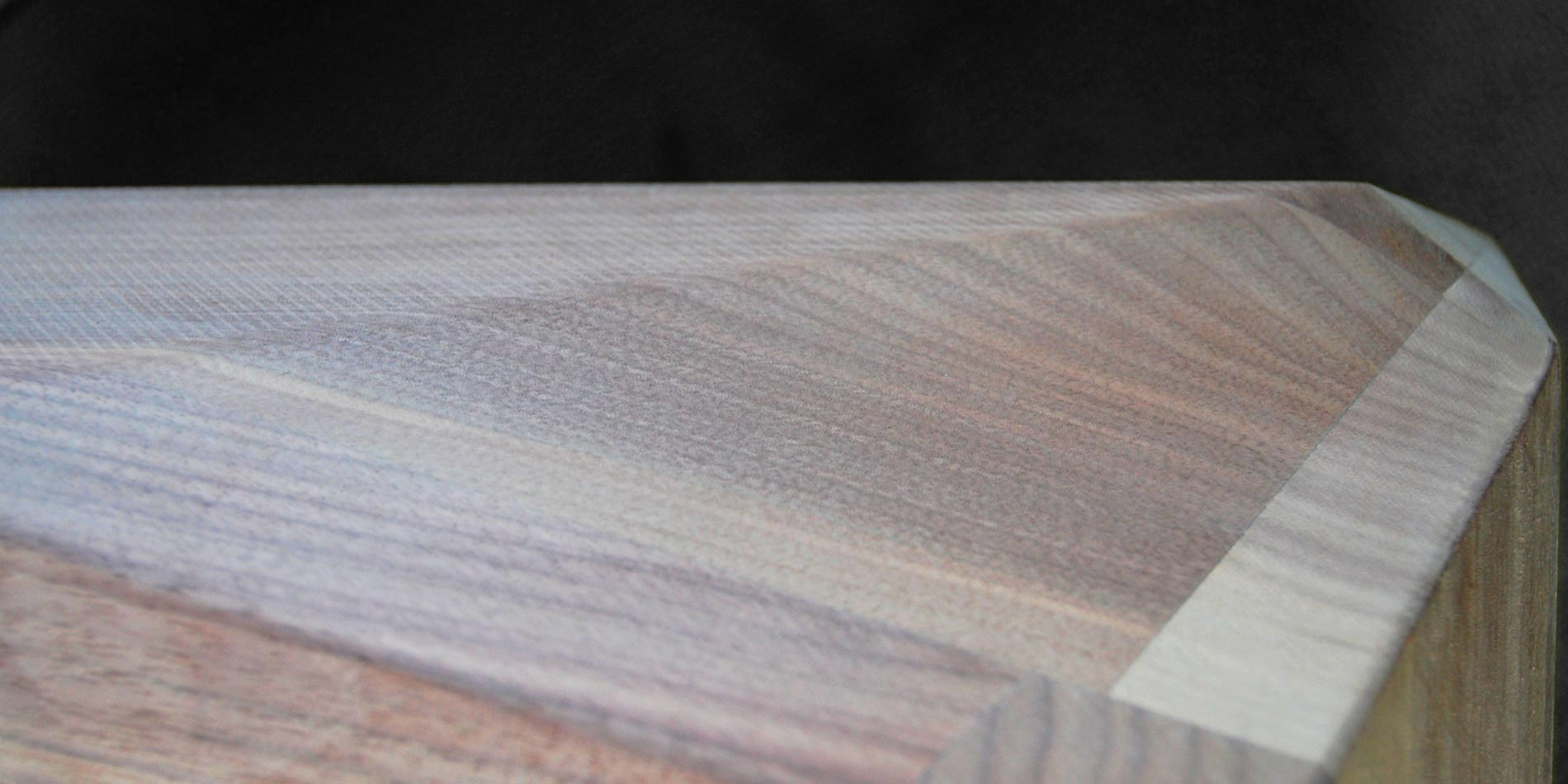

Diapason speaker units are made of Canaletto walnut from North America.

The solid wood is aged for at least 25 years to limit natural fibre variations before the staves are cut for the cabinet.

This choice has been determined by the special properties of this wood, first and foremost the pleasurable listening experience it produces, and the quality sound reproduction of a live performance.

Furthermore, strong, durable walnut creates solid, stable cabinets that last, and optimal acoustics are guaranteed through a living material that is continually communicating with the surrounding environment.

High Density Fiberboard is only used to produce large wooden floor standing speakers, which ensures optimal acoustic balance for larger dimensions.

The cabinetmaking process and timescales.

The production process is split into several phases and takes at least six months, to account for the rhythm of the seasons and lunar phases that can affect the properties of the wood.

Each cabinet is assembled using individually-cut staves, to create an overall design that provides the best acoustics and aesthetics, thanks to the solid wood grain.

Cabinets are then left to rest for months, to allow the wood to settle into the shape created, just as a good musical instrument demands.

Professional detail.

The speakers are fitted with drivers developed by SEAS in accordance with Diapason specifications, thanks to a partnership spanning decades, and connectors and metal components made by Diapason are connected using Van den Hul cables.

Components are selected for each cabinet in line with stereophonic precision criteria, and components are combined to maintain a low tolerance level of 1%.